News

The Phenomenon of Early Bearing Damage

Time:2021.04.22 Source:Roller Bearings Suppliers

The Phenomenon of Early Bearing Damage

When bearings are in use, the early damage phenomenon is a common failure of bearings. Early damage of bearings also has many forms, such as improper bearing matching, improper installation and improper maintenance, which will cause early damage.

1.Damage caused by unqualified size, shape and position accuracy of the workpiece matched with the bearing

If the shoulder of the workpiece shaft and the shell hole is not perpendicular to the matching surface, or the roughness of the bearing positioning surface is not qualified, and because of the shaft bending, it will cause the mutual skew of the inner ring and outer ring axes of the bearing and cause the local contact stress on the rolling surface of the ring and the roller to increase significantly, and then fatigue spalling and early damage will occur.

If the workpiece shell-hole is elliptical or conical, it will deform the ring and endanger the raceway, which will lead to premature wear and fatigue damage of the raceway. Similarly, if the geometric shape of the workpiece shaft and the bearing's matching journal is not correct, it will cause damage to the bearing's inner ring raceway. If the shaft diameter is too large, it may cause the inner ring to break.

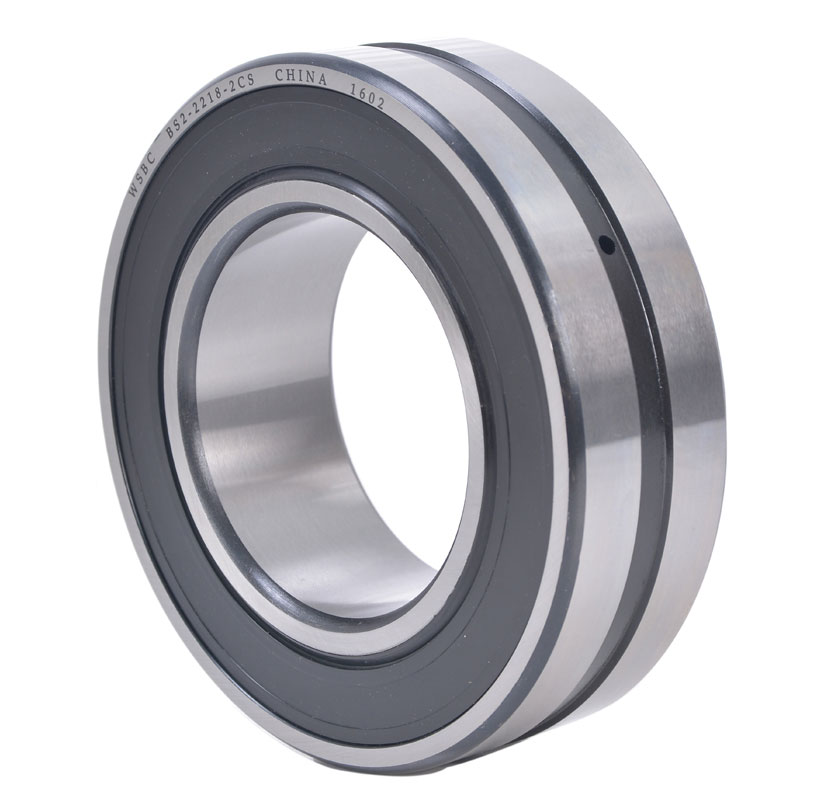

If the aperture of the shell is too large, it will cause the loosening of the outer ring and produce skid, which will aggravate the wear of the outer diameter of the shell hole and the outer ring. Need ZZ 22216-E1, click here to learn more.

2. Improper installation and operation mode causes damage to bearings

The inner component and outer ring of tapered roller bearings are respectively installed on the shaft and in the housing. During assembly, the raceway and roller of the ring can be damaged due to the tilt, impact or excessive assembly force. This damage, even if small, will aggravate the damage of the raceway. If there is a bump on the roller, the bearing will cause damage to the ring raceway after rotation.

In the process of installation, if the bearing is assembled in the way of pressing, special sleeve tools must be used, because the ring may crack or damage the end face of the ring by pounding the ring with the iron bar directly, or even cause the collapse of the inner ring rim.In order to avoid the generation of cracks, it is not suitable to use the iron bar to hit the ring directly but must add a copper gasket.

When using special sleeve tools to assemble the inner components, attention should be paid to the inner and outer diameters of the sleeve, so as to avoid the pressure of the sleeve on the end face of the cage resulting in deformation of the cage, and serious deformation may cause the scattering of rollers.

When handling and assembling, if the bearing components fall to the ground or are collided carelessly, the cage will be deformed.

The clearance adjustment between the outer ring and the inner component after bearing installation is also very important. If the clearance is too small, it will lead to a too high-temperature rise, accelerate wear and even bite to death. If the clearance is too large, additional radial runout and axial channeling will be generated, resulting in the relative displacement of the roller and the outer ring raceway and causing uneven local wear and noise. Only by proper adjustment can the normal operation of the bearing be guaranteed.

3. Damage caused by improper use and maintenance

When the bearing is working, if the lubricating oil is insufficient, the direct contact between metal and metal on the working surface will cause abrasions, heat and burns, reduce the original hardness of the bearing and then cause adhesion wear, and eventually lead to bearing failure.

Bearing before installation, such as the workpiece is not clean or add lubricating oil is not clean (e.g., mixed with sand, dust, dirt, etc.), or due to unreliable sealing and working in a dusty environment, some hard particles from entering the bearing raceway will cause of abrasive wear and the surface rendering traces grooves or small pitting, make the bearing clearance, lower accuracy, shorten service life.

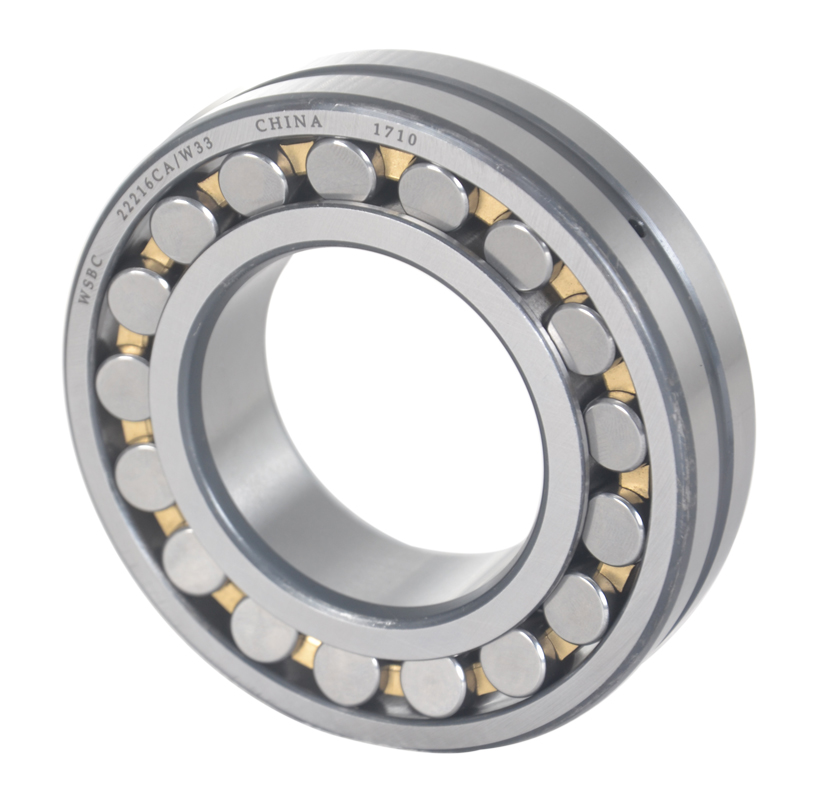

Bearing in use, such as by too large static load or impact load, is likely to make the inner and outer ring and roller contact area produces uneven plastic deformation -- indentation. The appearance of indentation will increase the vibration and noise of the bearing, increase the temperature, aggravate the wear, and then produce serious spalling, so that the bearing failure. Click here to learn more about ZZ 22219-E1.

Bearing in wet media and acid steam and other material caused by metal corrosion environment, such as bearing seal is not good, may cause corrosion. Corroded products mixed with lubricating oil will cause corrosive wear on the working surface of the raceway and rolling element, and cause surface spalling. Bearings in use if there is a current through the bearing, the current may break down the bearing oil film, produce electrical sparks, resulting in surface melting, forming small pits or strip pits.

In order to make the bearing work normally and reach the expected life, when selecting the bearing, the necessary calculation should be made for the main failure forms of the bearing. For bearings in general operation, the life should be calculated according to the contact fatigue failure and the rated dynamic load. For high-speed bearings, in addition to the calculation of life, but also necessary limit speed check; For bearings with low speed, static strength calculation should be carried out to prevent plastic deformation. After the early failure of bearings, it is necessary to carefully observe the damage, analyze the causes and take necessary improvement measures. In addition, the bearing combination structure design should be reasonable, to ensure full lubrication and reliable sealing, which is very important to improve the life of the bearing and ensure normal work.

ZZ Bearing (Shanghai) Co., Ltd (Aka ZZ Bearings) is the complete, one-stop Roller Bearings supplier & manufacturer. All products are qualified and have passed the ISO 9001 qualification. Here are some popular types of Angular Contact Ball Bearings, Send a quote and get the latest price of cheap bearings from ZZ Bearings.

Hot Topics

Copyright © ZZ Bearing (Shanghai) Co., Ltd All Rights Reserved. Sitemap

bearingsmanufacturing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings Factory China.