News

Characteristics of CC Type and CA Type Spherical Roller Bearings

Time:2020.01.21 Source:Roller Bearings Suppliers

There are two rows of spherical rollers, and the outer ring has a standard spherical raceway, which has excellent self-aligning performance. The bearing can still be used frequently when the shaft is bent or installed with different concentricity. The bearing capacity of this type of bearing is large.

Can withstand radial load The outer bearing can also bear axial weight in both directions, which has better impact resistance. Generally speaking, the operating speed of spherical roller bearings is low. It has self-aligning performance that other bearings do not have, and the self-aligning performance varies with different bearing size series.

This determines that the spherical roller bearing can be applied to some poorly aligned working situations, especially the two ends of the heavy-duty long shaft, which can avoid the misalignment caused by the bending of the beam and affect the operation of the bearing.

This are other types of rolling bearings. It has the characteristics and is applied in the sector of steel rolling, mining machinery, crusher, gearbox, steel rolling conveyor, reducer, and tension roller of rolling mill, etc. At present, CA type and CC type spherical roller bearings are the two most widely used structures.

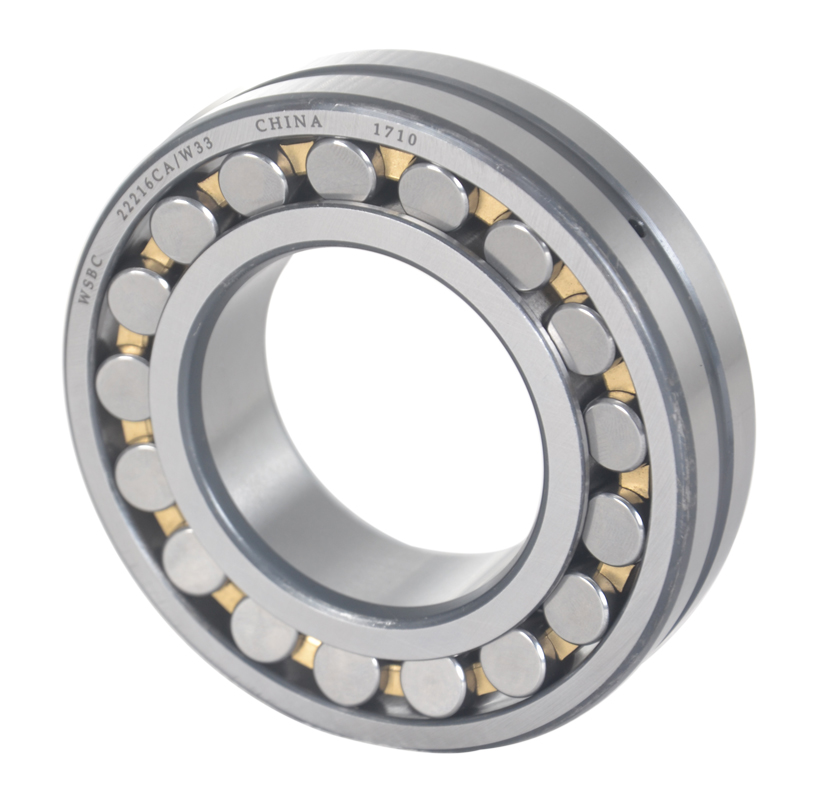

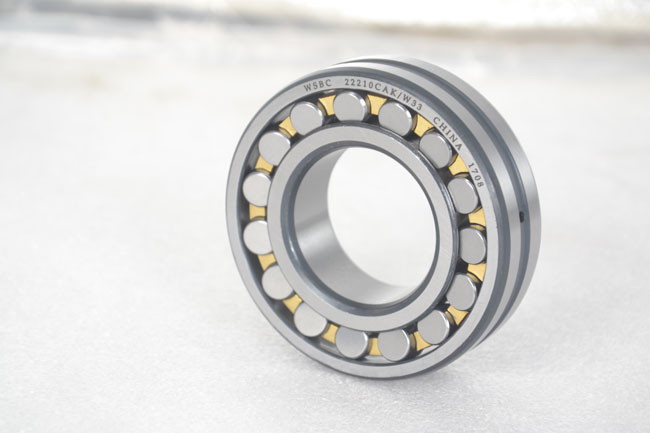

The two primary structures, CA spherical roller bearings and CC type spherical roller bearings are mainly distinguished by the presence or absence of ribs on the inner ring, and the cage is made of a solid or stamped frame.

Type CA: Car-made copper alloy cage with low noise and particular self-lubricating function. Less space occupied by rollers limits the size and number of rolling elements to limit its bearing capacity. The enclosure has a removable guide spacer. Small ribs on both sides of the inner ring

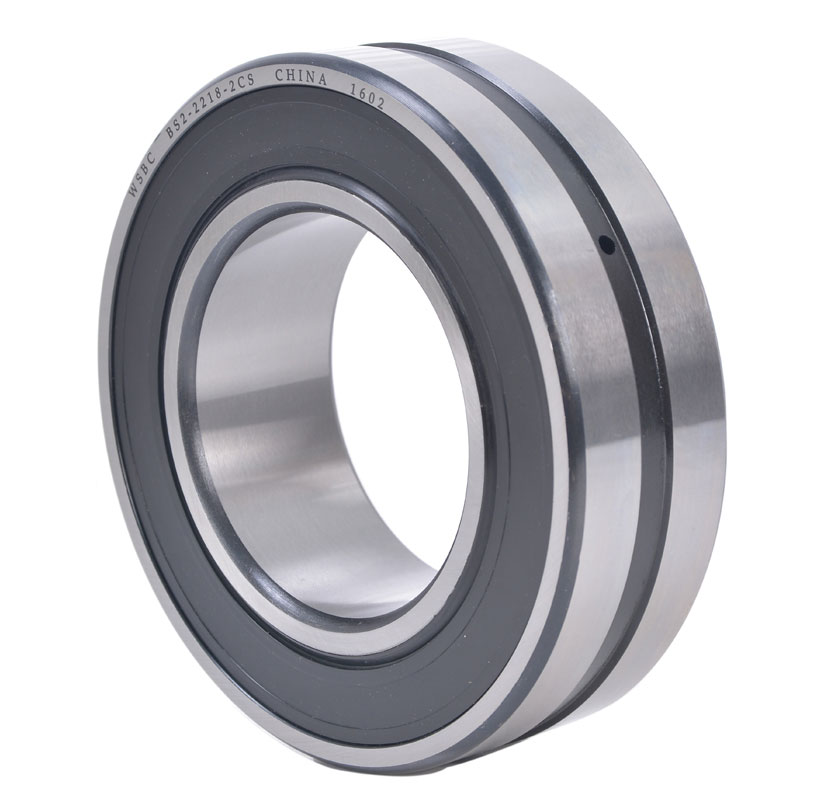

Type CC: The rollers are symmetrical. The inner ring has no middle ribs and no end ribs. The cage is split. The material is a stamped steel frame cage. A movable intermediate ring is designed between the rollers and rollers. Its function can effectively reduce the internal friction of the bearing, can effectively assist the rolling elements in the non-stressed area to correctly enter the load area, and also increase the limit speed of the bearing.

Therefore, in the field application, due to the CA type type spherical roller bearings structure of the cage, under the condition of the limited external dimensions of the bearing, it takes up a lot of internal space, which limits the external dimensions and number of the rolling elements to a certain extent, thereby reducing the bearing further. The possibility of improving its radial bearing capacity should be more used in the heavy-duty and high-speed working environment.

Moreover, compared with the CA structure, the spherical roller bearing of the CC structure has more considerable improvement in the tensile strength of the cage. At the same time, because the CC structure design occupies less internal space of the bearing than the CA structure design, it uses increased rolling The number of bodies and the change of the outer dimensions of the rolling elements can increase the radial bearing capacity of the bearing to a certain extent so that it can withstand higher axial bearing capacity than the CA structure design.

Hot Topics

Copyright © ZZ Bearing (Shanghai) Co., Ltd All Rights Reserved. Sitemap

bearingsmanufacturing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings Factory China.