News

Common Damage to ZZ Bearing Cage

Time:2021.04.14 Source:Roller Bearings Suppliers

What is the cage of the bearing?

As an important component of the bearing, the cage has a very large use effect. During the bearing use, the cage often appears damaged, which will seriously affect the use effect of the bearing, and even cause the bearing to be completely damaged and unusable. According to our understanding, ZZ Bearing (Shanghai) Co., Ltd will share some common damages related to ZZ bearing cages.

Common damages to ZZ bearing cages include:

1. The cage damage includes cage deformation, breakage and wear:

2. Breakdown of the column:

3. Deformation of the end face:

4. Wear of concave surface:

5. Wear of guide surface:

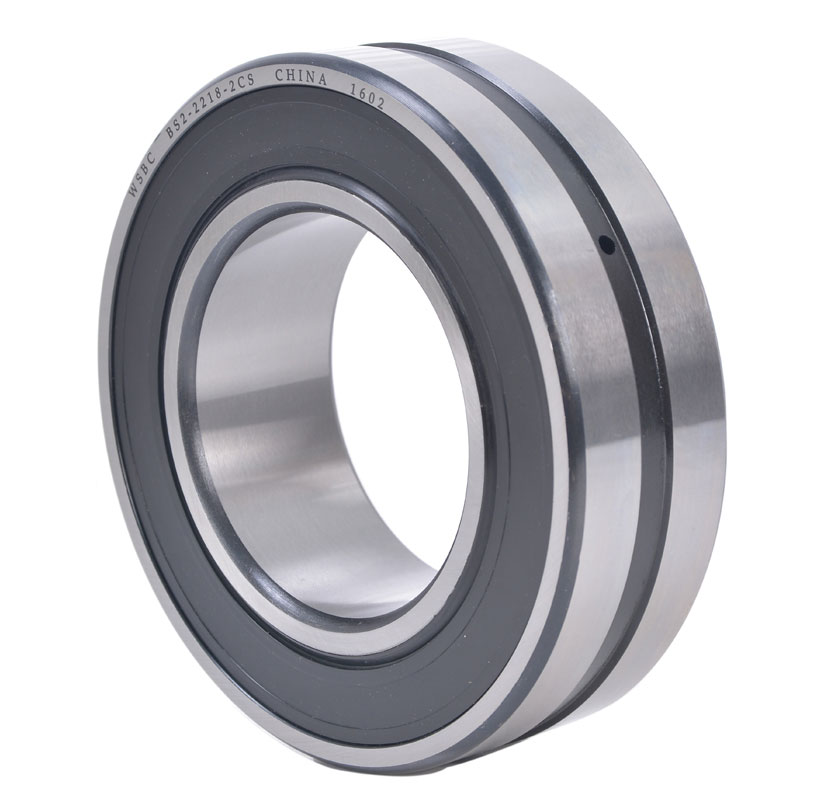

ZZ Bearing (Shanghai) Co., Ltd provides ZZ 24022-2CS online.

Common causes of damage to ZZ bearing cage are:

1. Poor installation (non-linearity of the bearing).

2. Poor use.

3. Large moment load.

4. Large shock and vibration.

5. If the speed is too high, it accelerates and decelerates rapidly.

6. Poor lubrication.

7. The temperature rises.

Common measures for ZZ bearing cage damage:

1. Check the installation method.

2. Check the load, rotation and temperature conditions.

3. Reduce vibration.

4. Correct the selection of the cage.

5. Change the selection method of lubricants and lubrication.

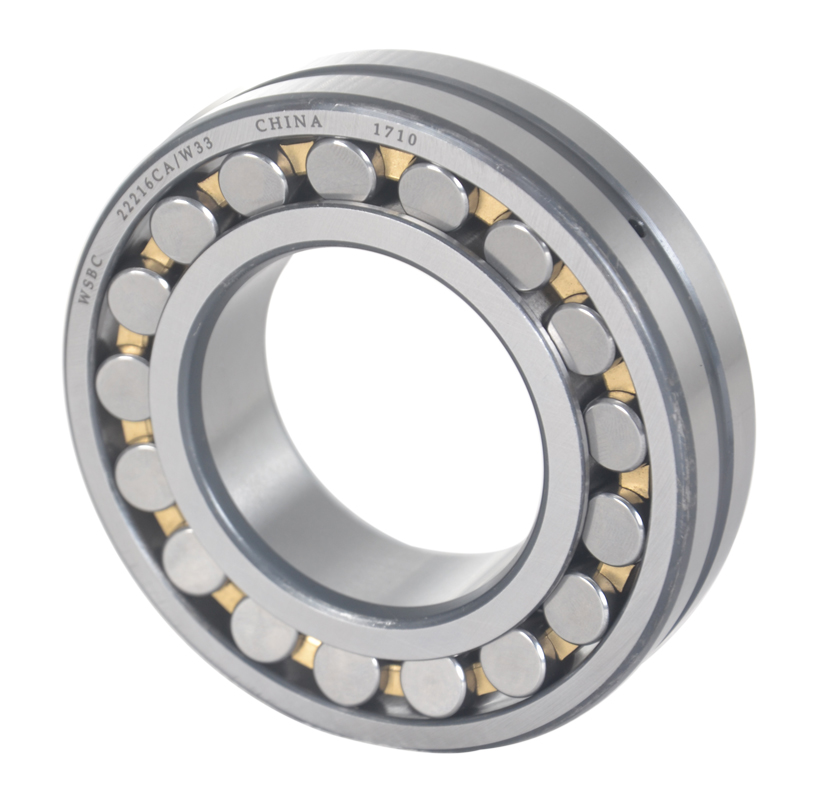

Click here to buy ZZ 24024-2CS.

ZZ bearing cage types and uses

The main purpose of the ZZ bearing cage is to separate the rolling elements to reduce the frictional heat generated by the bearing and to evenly separate the rolling elements to optimize the load distribution. The rolling elements are guided in the unloaded area of the bearing. For separate bearings, the rolling elements can be kept as one body when installing or removing one of the bearing rings.

The cage centered on the rolling elements allows lubricant to easily enter the ZZ bearing. The cage centered on the ring brings higher guidance accuracy and is usually used for bearings that must withstand the high speed, high vibration or inertial force generated during the overall movement of the bearing.

The main cage types are:

1. Stamped metal cage

The stamped metal cage (steel or brass sheet) is lightweight and can withstand high temperatures.

2. Machined metal cage

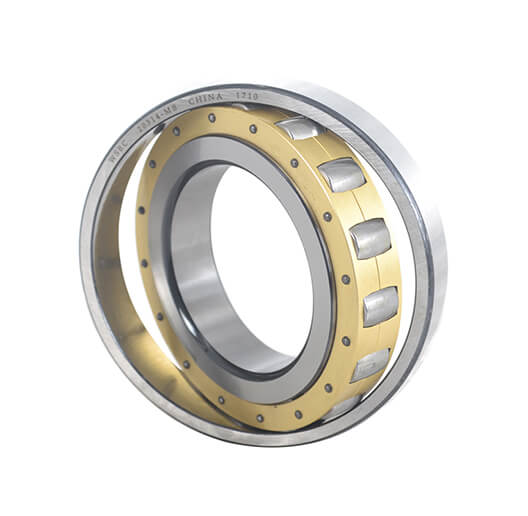

The machined metal cage is made of brass, steel or light alloy. It can withstand high speed, high temperature, high acceleration and high vibration.

3. Polymer cage

The polymer cage is made of polyamide 66 (PA66), polyamide 46 (PA46), polyether ether ketone (PEEK) or other polymer materials. The good sliding properties of the polymer material cage produce almost no friction, so it can allow high speed. In the case of poor lubrication, these cages can reduce the risk of sudden failure and failure side effects, because they can work for a period of time under limited lubrication conditions.

4. Pillar type cage

The steel pillar-type cage is a roller with perforated pins and is only used for large-size roller bearings. This kind of cage is relatively light and can accommodate a large number of rollers.

ZZ Bearing (Shanghai) Co., Ltd (Aka ZZ Bearings) is the complete, one-stop Roller Bearings supplier & manufacturer. All products are qualified and have passed the ISO 9001 qualification. Here are some popular types of Angular Contact Ball Bearings, Send a quote and get the latest price of cheap bearings from ZZ Bearings.

Hot Topics

Copyright © ZZ Bearing (Shanghai) Co., Ltd All Rights Reserved. Sitemap

bearingsmanufacturing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings Factory China.