News

Common Damage States Of ZZ Bearings

Time:2020.10.14 Source:Roller Bearings Suppliers

ZZ bearings will inevitably be damaged during daily use, and the damage state at each stage is different. If the user pays attention to the use of the bearing, the state of the bearing can be adjusted to further extend its service life.

In severe cases, metal peeling occurs on the contact surface and large areas of messy scratches occur; in general, ZZ bearing mechanical damage refers to the appearance of different levels of groove marks on the alloy surface of the bearing bush. Both contact surface damage and ablation are the main reason for bearing mechanical damage because it is difficult to form an oil film or the oil film is severely damaged.

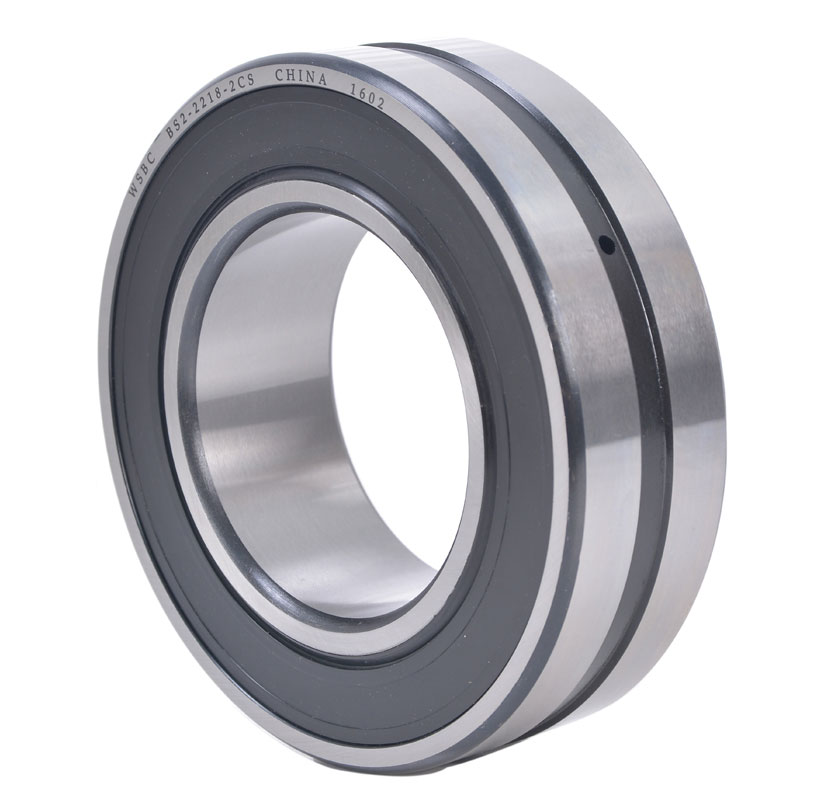

The outer surface layer undergoes plastic deformation and cold work hardening, and the ZZ bearing is repeatedly affected by the cylinder pressure impact load. Locally lose the ability to deform, gradually form grains and continue to expand, and then as the wear debris falls off, the loaded outer surface layer forms cavities. Generally, when cavitation occurs in the bearing bush, pits appear first, and then the pits gradually expand and cause cracks at the interface of the alloy layer. The cracks expand in the parallel direction of the interface until they peel off. The main cause of bearing cavitation is the sudden change of the cross-section of the structural elements such as the oil groove and the oil hole, which causes the oil flow to be strongly turbulent. The turbulent vacuum area of the oil flow forms bubbles, and then the pressure rises and the bubbles collapse to produce cavitation. Cavitation generally occurs in the high-load area of the bearing, such as the lower bush of the crankshaft main bearing. ZZ 24022-2CS online, contact us to buy it.

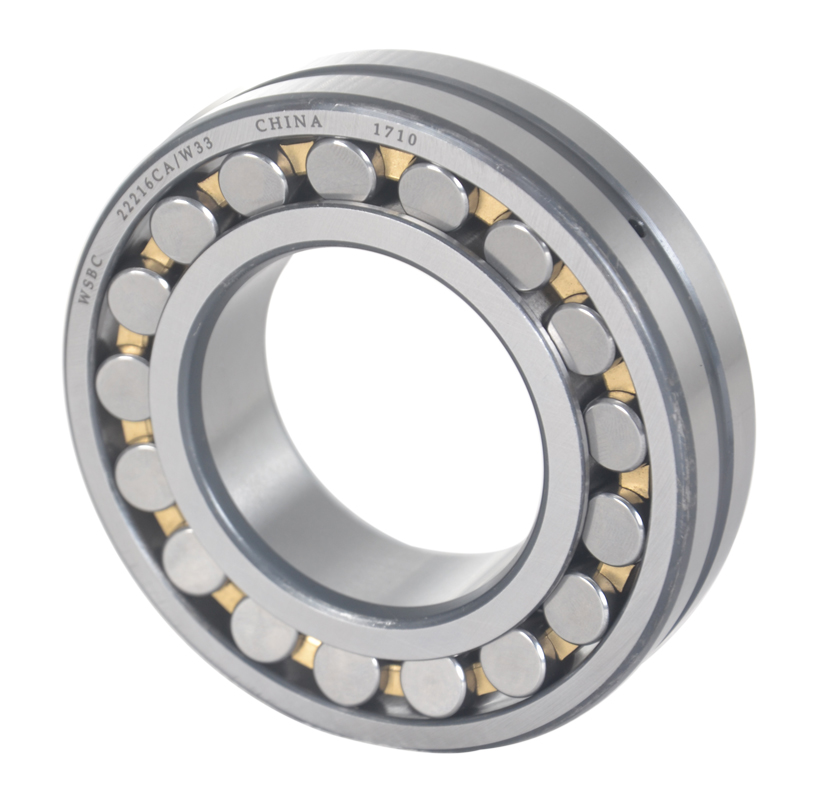

As the engine is overloaded, fatigue pitting of ZZ bearings means. Make the bearing work overheating and the bearing gap is too large, causing fatigue damage, fatigue pitting or fatigue fall off in the middle of the bearing. This kind of damage is mostly caused by overloading, excessive bearing clearance, or dirty lubricating oil and foreign matter mixed in it. Therefore, when using, you should pay attention to prevent the bearing from overloading and do not run at too low or too high speed; adjust the engine to a stable state when idling; ensure the normal bearing clearance to prevent the engine speed from being too high or too low; check and adjust the cooling The working condition of the system ensures that the working temperature of the engine is appropriate.

The chemical impurities (acid oxides, etc.) in the lubricating oil cause the bearing alloy to oxidize and generate acidic substances. The corrosion of the bearing alloy is generally caused by impure lubricating oil. Cause the bearing alloy to fall off locally, forming irregular tiny cracks or small pits. The main reasons for corrosion of bearing alloys are improper selection of lubricating oil, poor corrosion resistance of bearing materials, or rough engine operation and excessive temperature.

Local high temperature is formed, and there is direct contact between the journal and the friction pair of the ZZ bearing with tiny raised metal surfaces. In the case of lack of lubrication and poor cooling, the bearing alloy will be blackened or partially melted. This failure is often caused by the tight fit between the journal and the bearing; lack of lubricating oil pressure can easily cause the bearing to burn.

ZZ bearings mainly observe whether the rivet head is offset, skewed, slack, lack of meat or whether the "double eyelid" welding position is correct, and the riveting or welding quality of the frame is maintained. The welding point is too large or too small, and whether there is insufficient welding or welding Excessive causes of jamming of rolling elements. The above items are the key parts of the inspection of ZZ bearings, except for the above inspections. ZZ Bearing (Shanghai) Co., Ltd provides ZZ 24024-2CS, click here for more information.

To judge whether it meets the specifications I require. Let me share with you those parts that I should check. The inspection of ZZ bearings should be carried out under astigmatism, the appearance of ZZ bearings. Carefully observe the appearance and cracks of the bearing.

Such as abrasions, various mechanical scars. Scratches, crushes, bumps, etc. will cause the ZZ bearing device to be defective, cause eccentric load and stress concentration, and cause a decrease in rotation accuracy and service life. The latter two are defects that easily store moisture and dirt, rust, black skin and pitting. Easiest to develop into rust. Corrosion is a source of pollution that causes poor equipment, early wear and fatigue. Severe corrosion will cause the bearing to be scrapped.

Such as raw material cracks, various cracks. Forging cracks, heat treatment cracks and grinding cracks, etc., these cracks will become a source of stress concentration and rapidly expand during the operation of the bearing in the future, causing the bearing to rupture, and have a great impact on the life and working safety of ZZ bearings. In fact, for important-purpose bearings, the bearing factory has performed 100% magnetic or radiographic inspection on its component parts.

The parts of these two defects are not firmly bonded to the base metal, peeling and folding. Moreover, there are often different levels of decarbonization or carbon-lean phenomena around it, and the materials are easy to collapse, dent or wear, which is very detrimental to the life and accuracy of ZZ bearings.

ZZ Bearing (Shanghai) Co., Ltd has more than ten years of experience in bearing production and sales. The products are exported to more than 50 countries in the world and have won wide acclaim from customers. We are very willing to establish cooperative relations with you in the future. Welcome to contact us.

Hot Topics

Copyright © ZZ Bearing (Shanghai) Co., Ltd All Rights Reserved. Sitemap

bearingsmanufacturing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings Factory China.