News

How To Judge ZZ Bearing Damage

Time:2020.12.23 Source:Roller Bearings Suppliers

When using rolling bearings, due to their own quality and external conditions, their load-bearing capacity, rotation accuracy and anti-friction performance will change. When the performance index of the bearing is lower than the use requirement and cannot work normally, it is called bearing damage or failure. Once the bearing is damaged or other accidents occur, the mechanical equipment will stop rotating and its function will be impaired. So how do we judge that the bearing is damaged?

1. Vibration of ZZ bearing

ZZ bearing vibration is very sensitive to bearing damage, such as peeling, indentation, rust, cracks, abrasion, etc. will be reflected in the ZZ bearing vibration measurement, so it can be measured by using a special bearing vibration measuring device (frequency analyzer, etc.) The magnitude of the vibration can not be inferred by the frequency division. The measured value varies with the use conditions of the ZZ bearing or the installation position of the sensor, so it is necessary to analyze and compare the measured value of each machine in advance to determine the judgment standard.

2. Temperature of ZZ bearing

The temperature of the ZZ bearing can generally be estimated with the temperature of the outer surface of the bearing. It is more appropriate if the oil hole can be used to directly measure the temperature of the outer ring of the ZZ bearing.

Generally, the temperature of the ZZ bearing starts to rise slowly as the bearing runs, and reaches a stable state after 1-2 hours. The normal temperature of ZZ bearings varies with the heat capacity, heat dissipation, speed and load of the machine. If the lubrication and installation parts are proper, the bearing temperature will rise sharply and abnormally high temperature will occur. At this time, the operation must be stopped and necessary precautions must be taken.

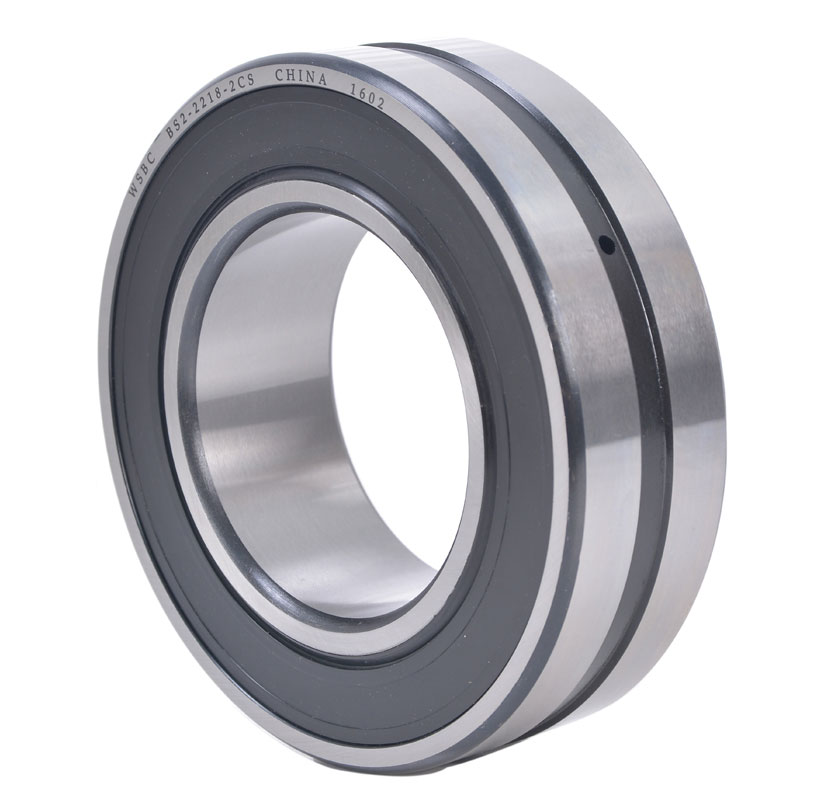

ZZ Bearing (Shanghai) Co., Ltd provides high-quality ZZ BS2-2222-2CSK.

The use of thermal sensors can monitor the working temperature of ZZ bearings at any time, and automatically alarm or stop when the temperature exceeds the specified value to prevent combustion shaft accidents. High temperatures often indicate abnormal conditions. High temperature is also harmful to the lubricant of ZZ bearings. Sometimes ZZ bearing overheating can be attributed to the lubricant of the bearing. Long-term continuous rotation of ZZ bearings at temperatures exceeding 125°C will reduce the life of ZZ bearings. Causes of high-temperature ZZ bearings include insufficient or excessive lubrication, lubricants. Containing impurities, excessive load, ZZ bearing ring damage, insufficient clearance, and high friction caused by oil seals.

Therefore, it is necessary to continuously monitor the temperature of the ZZ bearing, whether it is measuring the ZZ bearing itself or other important parts. If the operating conditions remain unchanged, any temperature change can indicate that a malfunction has occurred.

ZZ bearing temperature can be measured regularly with the help of a thermometer, such as a digital thermometer, which can accurately measure the ZZ bearing temperature and display it in units of °C or Fahrenheit. The important ZZ bearing means that when it is damaged, it will cause the equipment to stop. Therefore, it is better to install a temperature detector for this type of ZZ bearing. Under normal circumstances, ZZ bearings will have a natural temperature rise just after lubrication or relubrication and last for one to two days.

3. Sound of ZZ bearing

A sound meter is used to check the size and sound quality of the rolling sound of the ZZ bearing in operation. Even if the ZZ bearing is slightly damaged such as peeling, it will emit abnormal and irregular sounds, which can be distinguished by the sound meter.

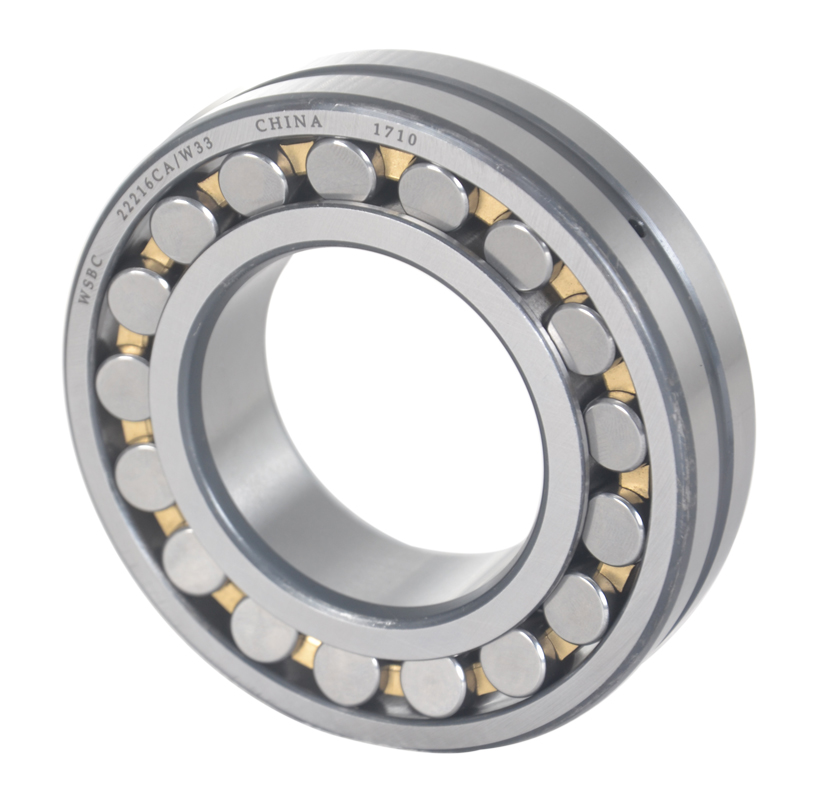

Click here for more details about ZZ BS2-2224-2CSK.

Listening is a very common way to use hearing to identify irregular movements. For example, using an electronic stethoscope to detect abnormal noise of a certain part is often used by experienced operators.

ZZ bearing will make a low whining sound if it is in a good continuous rotation state. If there are sharp hiss, squeak and other irregular sounds, it often indicates that the ZZ bearing is in a poor continuous rotation condition.

The sharp squeaking noise may be caused by improper lubrication. Inappropriate ZZ imported bearing clearance can also cause metallic noise. The dents of the concave track on the ZZ bearing outer ring track will cause vibration and cause a smooth and crisp sound. If it is caused by knocking scars during installation, the noise will also be generated. This noise will vary with the speed of the ZZ bearing.

If there is intermittent noise, it means that the rolling parts may be damaged. This sound occurs when the damaged surface is rolled over. Contaminants in the ZZ bearing often cause a hissing sound. Severe joint load damage will produce irregular and loud noises. ZZ bearing damage can be detected by hearing, but it is usually already here that the ZZ bearing must be replaced immediately. Therefore, a better method uses, for example, electronic condition monitoring equipment. The condition of the ZZ bearing can be estimated more accurately than the old method using a wooden stick.

ZZ Bearing (Shanghai) Co., Ltd (Aka ZZ Bearings) is the complete, one-stop Sealed spherical roller bearing supplier & manufacturer. All products are qualified and have passed the ISO 9001 qualification. Here are some popular types of Sealed spherical roller bearing, Send a quote and get the latest price of cheap ball bearings from ZZ Bearings.

Hot Topics

Copyright © ZZ Bearing (Shanghai) Co., Ltd All Rights Reserved. Sitemap

bearingsmanufacturing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings Factory China.