News

Identification And Use Of ZZ Bearings

Time:2020.08.19 Source:Roller Bearings Suppliers

Whether the outer packaging is clear: Under normal circumstances, our brand's products have special designers to design the outer packaging, and arrange for production in factories that pass the production conditions, so the packaging is very clear and unambiguous from lines to color blocks .

Whether the steel stamping is clear: Brand words, labels, etc. will be printed on the ZZ bearing body. The fonts are very small, but most of the products produced by the factory use steel stamping technology, and they are pressed before heat treatment. Therefore, although the fonts are small, they are deeply concave and very clear.

Whether there is noise: Hold the inner sleeve of the ZZ bearing with your left hand, and turn the sleeve with your right hand to hear whether there is any noise. Due to the backward production conditions of most counterfeit and inferior products, it is completely hand-crafted and workshop-style. During the production process, impurities such as sand will inevitably be mixed into the ZZ bearing body, so noise will be generated when rotating.

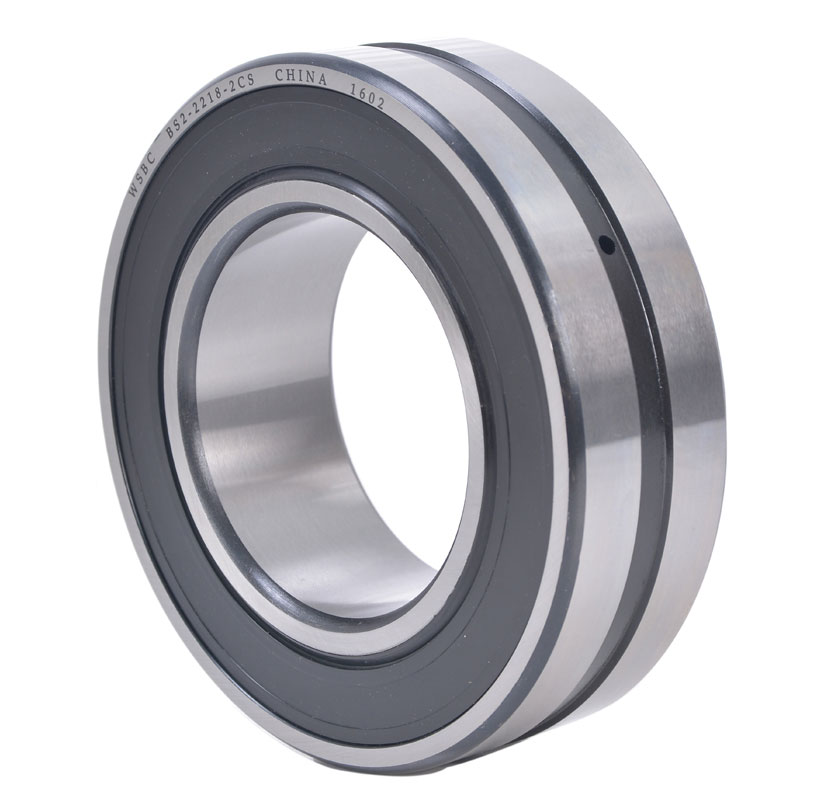

Whether the chamfer is uniform: the so-called chamfer of the ZZ bearing, that is, the junction of the horizontal plane and the vertical plane, the counterfeit bearing is not handled satisfactorily at these corners due to the limitation of production technology.Click here for more information about ZZ Bearing 22228-2CS.

After identifying the quality of the bearing, take a look at how to use ZZ bearings correctly.

First of all, when disassembling the ZZ bearing, use a suitable puller to pull the ZZ bearing out. When the size, shape and accuracy of the ZZ bearing assembly hole in the bearing seat are not good, the ZZ bearing will be affected by it, and it is impossible to develop the best. Features. For example, if the dimensional accuracy and shape accuracy of the common parts of the ZZ bearing housing are not good, the outer ring of the ZZ bearing is deformed and the roundness of the inner hole of the ZZ bearing is deteriorated; if the shoulder accuracy is not good, the outer ring and the roller of the ZZ bearing will occur. Tilting, aggravating the concentrated load, will reduce the fatigue life of the ZZ bearing, and more serious will lead to the damage and sintering of the holding frame; if the accuracy of the spindle ZZ bearing in the inner ring of the ZZ bearing is not good, such as size, roundness, cylindricity, and ripple The accuracy of the degree, roughness, position and other aspects will clearly lead to the increase of the vibration value of the whole spindle.

Secondly, the complete set of ZZ bearings undergoes strict and fine selection before assembly. Therefore, the scattered ZZ bearing parts cannot be exchanged and used without re-measurement and selection before the user uses it.

Third, about the cleaning of the spindle ZZ bearings and spindle feet. Because of the compact structure of the spindle foot, there are many other parts in the spindle foot cavity. The cleanliness of the ZZ bearing installation method of Qingdao Ruijing ZZ bearing electromechanical ZZ bearing will also affect the cleanliness of the ZZ bearing task cavity. Therefore, it is a more reasonable process to pre-clean the spindle foot parts before the assembly, and in the future assembling the assembly, it is a more reasonable process to clean the assembly spindle foot including the ZZ bearing.

Fourth, ZZ bearings should not be bumped and impacted during assembly. Bumps and impacts are likely to cause collisions between ZZ bearing parts and cause ZZ bearings to lose effectiveness.

Fifth, pay attention to the angle and strength of the hemming when the bearing seat is hemmed to prevent the unreasonable hemming from deforming the ZZ bearing parts.

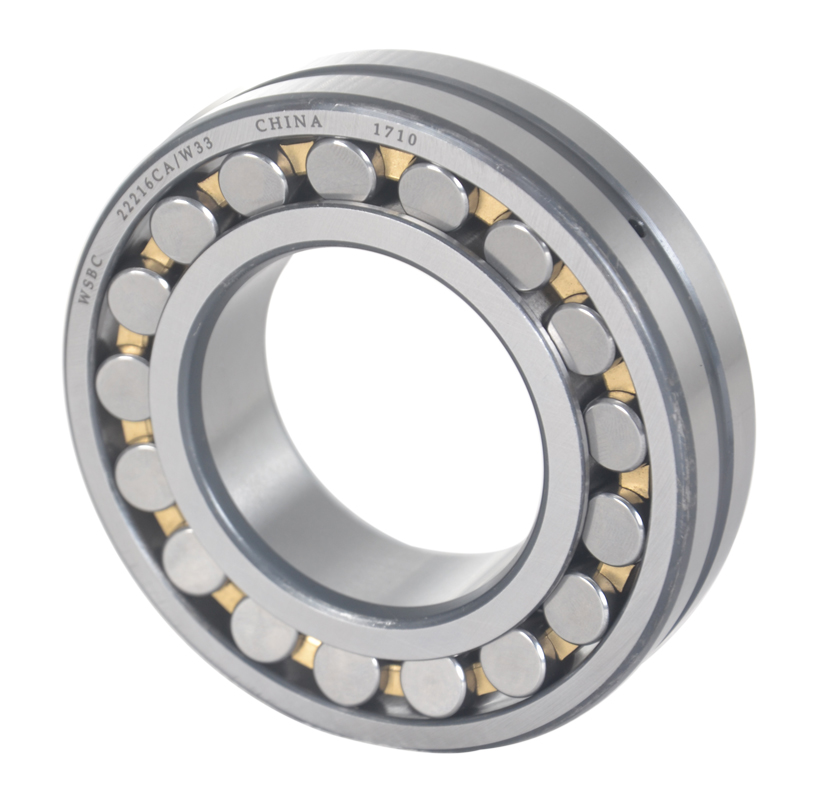

Sixth, for ZZ bearings that have exceeded the anti-rust period or have a long storage time, the fatigue life of rolling bearings has considerable development potential, which can show rust or the roller sticking due to the drying of the anti-rust oil.ZZ Bearing 22230-2CS online, contact us for more details.

Checking the condition of the machine in operation and preparing a thorough inspection plan has become more and more serious. Among them, ZZ bearing is the focus of attention, because it is the most important rotating part in all machines. Condition monitoring is an important part of preventive maintenance. Early detection of ZZ bearing damage to avoid equipment shutdown during unplanned maintenance due to ZZ bearing damage.

However, not all of them are equipped with this advanced instrument. In this case, the operator or maintenance engineer of the machine must be highly alert to the "fault signals" of the ZZ bearing, such as noise, temperature and vibration. "Listen" , "Touch" and "observation" are three important factors.

Touch

High temperature often indicates that the ZZ bearing is in an abnormal condition. High temperature is also harmful to the lubricant in the ZZ bearing. Sometimes the ZZ bearing overheating can be attributed to the lubricant of the ZZ bearing. If the ZZ bearing is operated at a temperature exceeding 125 degrees Celsius for a long time, it will reduce the ZZ Bearing life. The causes of high temperature ZZ bearings include: insufficient or excessive lubrication, lubricants containing magazines, excessive load, ZZ bearing damage, insufficient clearance, and high temperature friction caused by oil seals.

Therefore, it is necessary to continuously monitor the temperature of the ZZ bearing, whether it is measuring the ZZ bearing itself or other important parts. If the operating conditions do not change, any temperature change may indicate that a failure has occurred.

Regular measurement of ZZ bearing temperature can be done with the help of a thermometer, which can accurately measure the ZZ bearing temperature and display it in degrees Celsius.

The important ZZ bearing means that when it is damaged, it will cause the equipment to stop. Therefore, this type of ZZ bearing should preferably be equipped with a temperature detector.

Under normal circumstances, ZZ bearings will have a natural temperature rise after just lubrication or relubrication and last for one or two days.

Observed

If the ZZ bearing is well lubricated and properly blocked debris and moisture, it means that the oil seal should not be worn. However, it is best to visually inspect the ZZ bearing and periodically check the oil seal when opening the ZZ bearing box. Check the close to the ZZ bearing Keep the oil seals in place to ensure that they are sufficient to prevent hot liquid or corrosive liquid or gas from penetrating into the ZZ bearing along the axis. The protection ring and labyrinth oil seal should be greased to ensure maximum protection. The oil seal should be replaced as soon as possible if it is worn.

Hot Topics

Copyright © ZZ Bearing (Shanghai) Co., Ltd All Rights Reserved. Sitemap

bearingsmanufacturing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings Factory China.