News

ZZ Separable Bearing Installation Method

Time:2021.02.17 Source:Roller Bearings Suppliers

Overview of the separate bearing

The separate bearing is a relatively important part. If it is not well maintained and malfunctions, it will not only cause economic losses but also once disassembled and assembled is very troublesome and requires a lot of man-hours. Therefore, understanding the correct installation method of the separate bearing and the cause of the failure, and performing reasonable maintenance and maintenance during use, is of great significance to prolong the service life of the separate bearing, increase labor productivity, and obtain better economic benefits.

Correct installation method of the separate bearing

The installation of separate bearing can be easily installed on the shaft or bearing seat because the inner ring and the outer ring are convenient. At this point, it should be noted that when the shaft with the inner ring installed is inserted into the bearing box with the outer ring installed, it should be kept concentric as much as possible to prevent the rolling body and the raceway from being scratched.

When installing non-separable bearings where the inner ring of the ZZ bearing is tightly fitted with the shaft and the housing seat of the outer ring is loosely fitted, the installation of the separable bearing can be easily installed on the shaft or the bearing seat due to the inner ring and the outer ring. At this time, it should be noted that when the shaft with the inner ring installed is inserted into the bearing box with the outer ring installed, it should be kept concentric as much as possible to prevent the rolling body and the raceway from being scratched.

When installing the non-separable bearing with a tight fit between the inner ring and the shaft of the ZZ bearing and the loose fit of the outer ring bearing seat, you can use a press to install the bearing on the shaft, and then install the shaft and the bearing together in the bearing seat In the hole, if the bearing is small, you can use a soft metal hammer to lightly tap the end surface of the ring to force the bearing to work, but the striking force must be evenly distributed on the bearing ring. When the outer ring of the bearing and the hole of the bearing seat are tightly fitted, and the inner ring and the shaft are loosely fitted, the bearing can be installed on the shaft first.

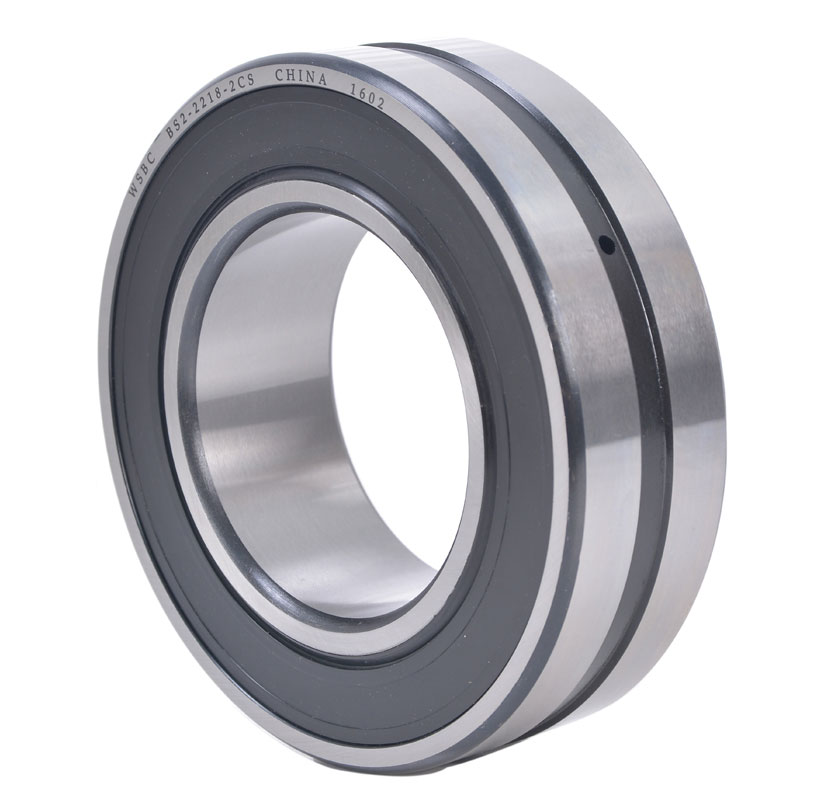

ZZ Bearing (Shanghai) Co., Ltd provides high-quality ZZ 23022-2CS.

When the bearing ring and the shaft or bearing seat hole are tightly matched, a special installation sleeve barrel should be used to press the bearing onto the shaft or bearing seat at the same time.

When the size of the ZZ bearing is large, it is difficult to use cold installation due to the large installation force required or the large interference of the bearing under heavy load, so it is necessary to heat the bearing inner ring or bearing seat in advance Then install. During hot installation, the heating temperature should be strictly controlled.

When heating bearings, the maximum heating temperature should not exceed 1200C, generally 80~1000C. Bearings with dust caps or seals cannot be heated, otherwise, the lubricant will be lost. The heating method can use electric induction beauty, oil bath heating and other methods.

In order to choose the most suitable fit, the following must be considered:

1. The direction of the load

2. Load characteristics

3. The size of the load

4. Temperature conditions

5. Installation and disassembly conditions

About ZZ bearings installed in thin-walled bearing housing holes or hollow shafts, you must provide an interference fit that is larger than normal.

Click here to buy ZZ 23024-2CS. We have enough stock.

Split bearing housings are not recommended for high-precision or tight seat hole matching, otherwise, the split bearing housing may cause deformation of the outer ring.

The abnormal sound of ZZ bearings

The abnormal sound of ZZ bearings is a new problem and an old one.

It is a new problem because it is a problem exposed in the process of bearing development from low vibration value to the quiet direction in recent years, and the quality of bearings is constantly improving.

Said it is an old problem, because in the early pursuit of low vibration, there is no higher requirement for the sound quality of the bearing, but the abnormal sound of the bearing exists objectively. Once the vibration value of the bearing is steadily reduced to a certain level, the abnormal sound popped out.

For most types of ZZ bearings with low noise, large vibration value and abnormal noise, their vibration peaks are arranged in order from low to high: low noise bearings, bearings with abnormal noise, and large vibration values Bearing. This shows that the peak value of the vibration acceleration level of the bearing with abnormal sound is between the low noise and the bearing with a large vibration value. Therefore, the misjudgment rate of using the vibration effective value to evaluate the abnormal sound of the bearing is high.

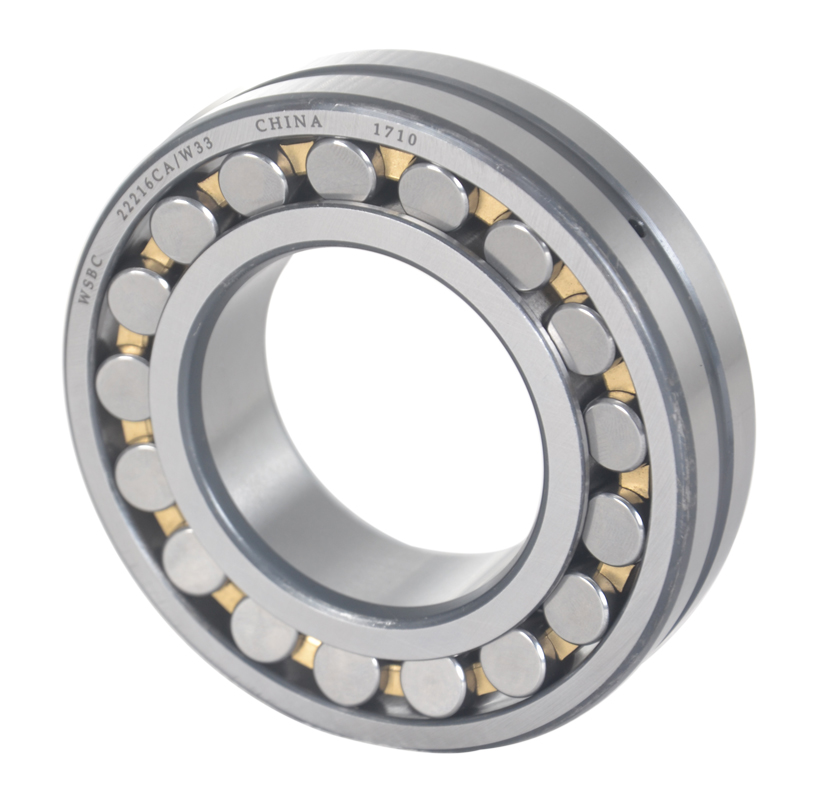

ZZ Bearing (Shanghai) Co., Ltd (Aka ZZ Bearings) is the complete, one-stop Spherical Roller Bearings supplier & manufacturer. All products are qualified and have passed the ISO 9001 qualification. Here are some popular types of Spherical Roller Bearings, Send a quote and get the latest price of cheap bearings from ZZ Bearings.

Hot Topics

Copyright © ZZ Bearing (Shanghai) Co., Ltd All Rights Reserved. Sitemap

bearingsmanufacturing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings Factory China.